SunMaxx Solar Thermal Webinars

We’ve prepared a series of simple webinar and educational videos to share some of both our own experience and customers experience with best practices to install your solar thermal system.

SunMaxx Solar Thermal Training Videos & Webinars

- Show All

- Commissioning

- Flat Plate Accessories

- FlowMaxx Solar Piping

- Introduction to Solar Hot Water

- Maintenance

- Solar Hot Water System Design

- UniMaxx Solar Pump Stations

Flat Plate Collector Compensator Installation

How to insulate stainless steel lineset

How to connect quick connect fittings with stainless steel pipe

Winter Solstice Celebration Reasons – What is it?

What is the Winter Solstice and why is this important for solar hot water systems?

What Angle to tilt your solar hot water collectors

A short introduction on what angle you should tilt your solar hot water collectors.

The Science of Evacuated Tubes

The science of evacuated tubes. Short introduction on how they work.

Part 2 of this webinar series.

How to change or replace heat pipes in evacuated tube collector

Quick video on how to replace your evacuated tube heat pipes (replace or to remove if you have issues with producing too much heat!) .

Charging the Solar Hot Water System

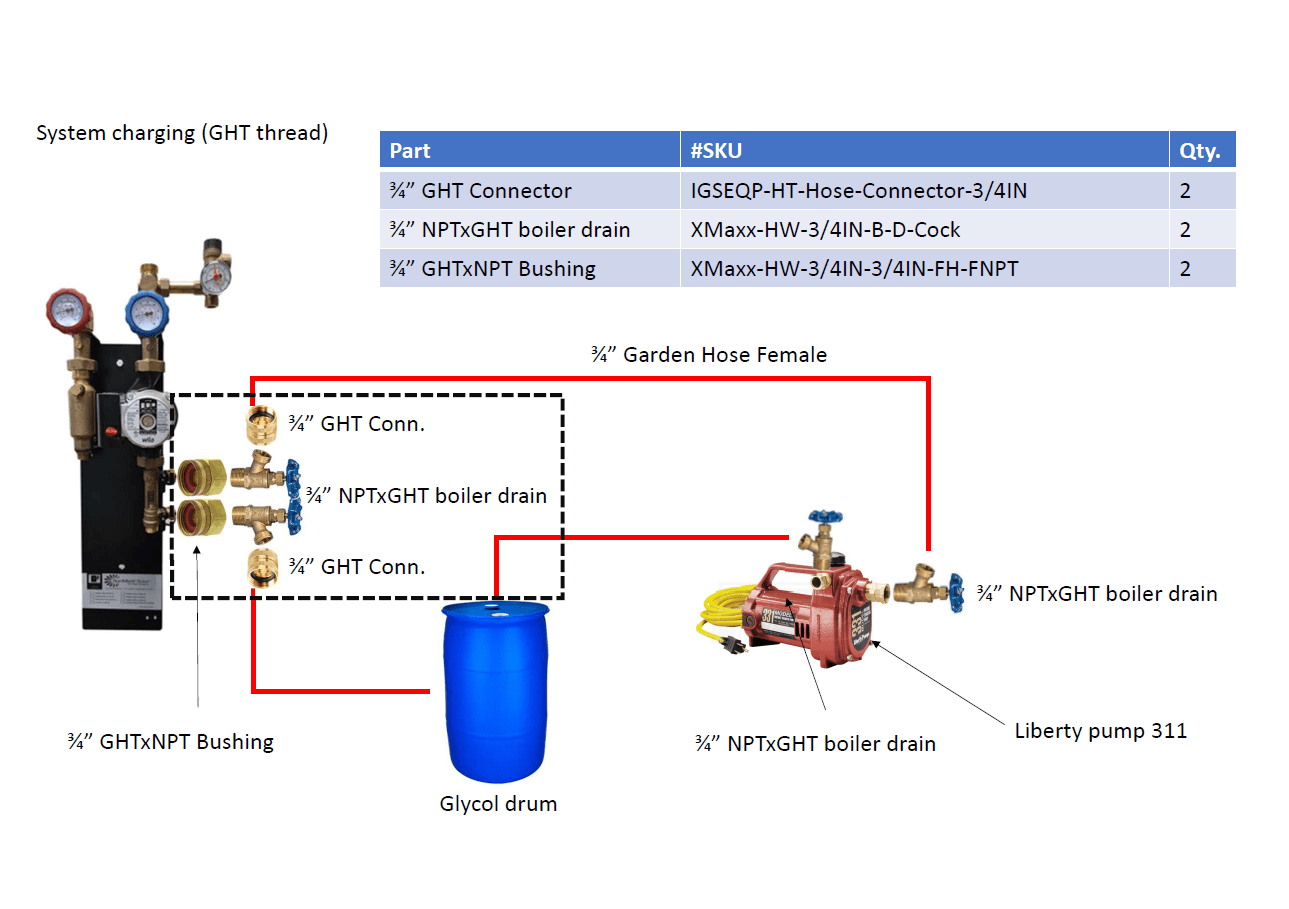

System charging kits schemes

Parts in black box should be pre-assembled. Make sure you are using proper threading kit.

System charging steps

- Makes sure air vents on roof are closed (or glycol will leak out).

- Prepare transfer pump, hoses, and glycol for charging of solar loop.

- You will need mixture of 50% glycol, 50% water. Approximately 0.5 gal per one collector.

- Connect discharge pump to top connection on solar pump station

- Connect return hose to glycol drum (from the bottom connection on solar pump station) .

- Prime transfer pump (make sure you have pressure).

- Open fill/flush port valves on pump station (black valves).

- Make sure flow meter valve is turned perpendicular to the valve body (this is fill mode).

- Turn the solar pump on in manual mode (usulally relay 1); which will turn on the solar pump.Make sure your red / blue temp gauges are not closed (they are open).

- Start transfer pump, build pressure until glycol returns from return hose into glycol drum.

- Make sure suction hose (from transfer pump) is installed below the water line in the glycol drum.

- If you have multiple collector banks; isolate the cold supply on the upper bank (lets the system fill the lower bank first. Let glycol run for 10‐15 minutes; most air should be purged out of the system (you will notice steady stream of glycol from the return line)

- Next, open the upper bank balancing valve and close the bottom bank, let run for 10‐15 minutes

- Open both valves on the collector banks.

- Begin to close the return valve on the fill/flush ports (this will allow for building of circulation loop pressure. Build pressure to 50+ PSI (as long as you have some flow coming out into the glycol drum).

- High pressure pushes the air out of the fluid.

- Bleed the air out of the air bleeding points (air vents in collectors, air vent on pump station, air vent on pump).

- Let system circulate at this pressure for 20‐30 minutes

- Close the fill/flush ports, turn off the transfer pump.

- Turn the flow meter valve to the verticle position; leave the pump in manual mode.

System charging videos

Charging setup

Charging procedure

Pump priming

Return hose

Have a project?

Let's get started.

Contact our technical team to get help with design and planning specifications on your next solar thermal project.

Engineering

Design Solutions

SunMaxx Solar offers custom engineering solutions to help navigate the complexities of planning and installing a solar thermal system.

From feasibility studies to full project management services, our team has participated in over 4,000 projects worldwide. Find below a list our standard services we provide for both commercial and residential applications.

How much do engineering services cost?

Our engineering services are sold in both packages and hourly rates depending on the size and scope of your project. Our aim is to deliver cost effective engineering services specifically designed for solar thermal customers.

Our Engineering Solutions Include:

We provide complete turnkey project management from design to commissioning of your project. Our services include utilizing existing sub-contractors or introducing new contractors to facilitate the construction of your project.

Navigating the building code and planning requirements can be expensive and time consuming. Our in-house engineering team has extensive experience in working with planning and permit offices around the world, specifically for solar thermal systems.

Our services include preparing of full plan sets and permit packages to be submitted to the building departments.

Need a solar feasibility study for your next project? Let us help prepare energy models and financial feasibility reports for your upcoming project.

Typical projects fall in the commercial and industrial sector for this service plan.

Have a custom project which requires a specific heat transfer station or mounting system detail? Our engineering team can help provide full construction drawings for "on roof" or "off roof" solar thermal sub-assemblies.

Let our engineering team prepare custom solar thermal energy simulations using specialized solar thermal energy modeling software.

We offer remote and in-person full technical training on solar thermal system design and planning.

Additionally, we offer in facility training at our renewable energy training center located in Upstate New York.