119 Gallon Pressurized Electric Backup Tank With 2 Heat Exchangers

$3,479.94

- 119 gallon StorMaxx SE Tank

- 2 heat exchangers and electric element

- for 2 collector ~ 89 ft2

- for domestic hot water primarily

- 27.6in x 74.6in (DxH)

- Description

- Additional information

Description

SunMaxx StorMaxx™ SE Solar Tank water heaters, offer a cost-effective water heating alternative. These tanks include a back-up electric element, which allows for the versatility of a stand alone solar water heater, or pipe it in as a pre-heat solar system.

The StorMaxx™ SE is a durable porcelain enamel, glass-lined tank. Highly resistant to aggressive water. Not susceptible to damage due to the presence of chloride in the water. Built to last-inner tank is hand-crafted from heavy gauge steel. Longer life equals to higher return on investment. Outer jacket made from steel and powder coated for a lasting, durable finish.

StorMaxx™ SE Tank Features

- Suitable for 3 collector ~ 88.5 ft2 required

- Less Heat Loss up to 30 %

- Sensor tube included

- 2 Heat Exchanger inside the tank

- Designed primarily for domestic hot water

- 120 gallons storage tank

- 4500W Electric back-up Element-UL listed

- Serpentine Coil: single wall steel plate (ST 37.2)

- 27.6 IN x 74.8 IN (DxH)

- 2 IN insulation

What parts & accessories do I need?

Technical Details

Technical Spec:

- Volume: 119 gal

- Weight: 375 lbs

- Diameter: 27.6 IN

- Height: 74.8 IN

- # of HX: 2

- Insulation: 2 IN

- Working pressure 150 psi

- Max working Temperature: 203 °F

Features:

- 4500W Electric back-up Element-UL listed

- Factory installed temperature and pressure valve-CSA listed

- Factory installed brass drain valve-accessible, tamper-proof

- 2″ Non-CFC foam insulation-decreases standby heat loss

- 1-1/2″ coil diameter-larger diameter, results in higher recovery and less pressure drop through the coil, smooth surface on coil resists lime build up

- Sediment reduction inlet-available on the SE-80 and SE-119. Reduces sediment buildup on the tank bottom, increasing operating efficiencies and tank life

- Two magnesium anode rods-inhibit corrosion and maximize tank life. Electrolysis attacks the anode rods, not the tank

- Factory installed dielectric nipples on boiler connections-provides greater insulating protection

Connections:

- Warm Water Port Size: 3/4” NPT M

- Cold Water Port Size: 3/4” NPT M

- Safety Valve Connection: 3/4” NPT F

- Drain Valve Connection: 3/4” NPT F

Can you install ports in the bottom of the tanks?

Installing the ports in the bottom parts is not recommended by SunMaxx Solar ™ . They are always installed in the top of the NP tank due to some reason. Firstly the water is filling the tank to determined level. Ports are located above the water surface - no leaking water from tank. Locating the ports in the bottom parts can cause the leaks and have to be well isolated. Moreover, parts for inslling can cost a huge amount of money. That all issues may lead to some problems, that SunMaxx Solar ™ install ports on the top locations.How do I clean the tanks?

Cleaning the tanks is a process which is simple but easily can cause some troubles. Cleaning the outer layer you can you a pressure washer - it should work. When you want to clean inner site you can also use that device. Before you start remove all the heat exchanger coils carefully, don't cut the rubber membrane. Also the pressure washer can cause some damages in the surface of it, so remember to wash it carefully. After processes place all compactness on their place.How can you use the tank in drain back applications?

The drain back tank are perfect solution for solar thermal system in the area where climate is challenging. That means extremely hot or cold temperatures. These tank allows all the water in the system (collector and piping) to drain into the tank reservoir. The water also protects the system form freezing and overheating. Below there is a the simplest scheme of the system with basic components.

How do I check the water level inside of the tank?

The are a lot of different methods how can you check the water level and measure it. The simplest method is to use the wooden stick (length is greater than tank height) or line ended with some heavy weight. After that you can measure the level with measuring tape. For sure you can find some sophisticated methods but using simple one you will reduce amount of money spend on a special equipment.How can you do it in a 5 simple steps:- Remove the top lid of the NP tank.

- Take a stick or line and put it to the tank (in both situations this items should touch the bottom lid).

- Mark a level of water and take out stick or line.

- Measure the distance with a measuring tape - you will instantly know the level of water in your tank.

- Put the top lid on the NP tank to close it.

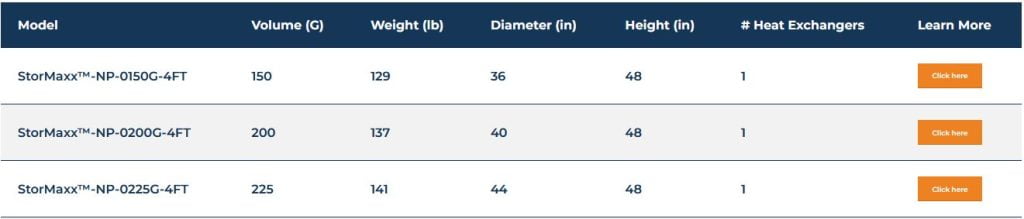

How many heat exchangers can I fit in the tank?

The amount of heat exchangers which can be fit in the tank mainly depends on the size of the NP tank and its increasing with the diameter of the tank. Before you buy the heat exchanger please check two parameters:- The height of the NP tank - heat exchangers can't be higher that tank

- Maximum amount of HX which can be fit in the tank

How to connect heat exchangers

Connecting the heat exchanges depends on a customer requirements. The number of HX depends on some factors like tanks size, number of collectors and heat requirements. There are some possibilities to connect the heat exchangers. In our offer 80/80 Stacked 3/4" Corrugated Stainless Steel HX and 90 3/4" Corrugated Stainless Steel HX. Customer can connect HX in few ways. Only Solar Side, no connection in DHW side or both side connected.

DHW&Solar Side Connection - Stacked HX

Connection used in stacked HX. One of the most common type of HX connection. Requires some additional elements like HX Connection Tees. Applicable for connection HX on DHW side and Solar Side. For more accurate questions you can contact the engineering team.

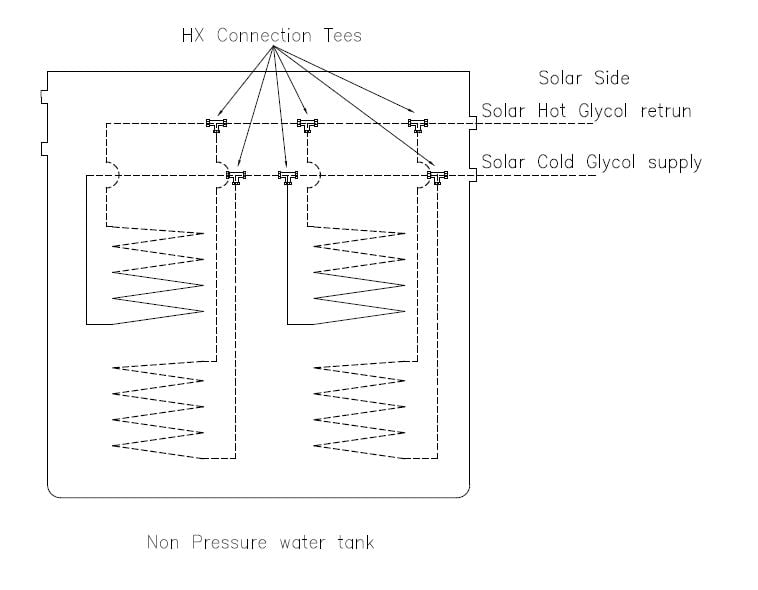

Solar Side Connection - Stacked HX

Connection used in stacked HX. Requires some additional elements like HX Connection Tees. The connection type uses only the Solar Side ports. There is no heat exchanger connected with DHW Side.

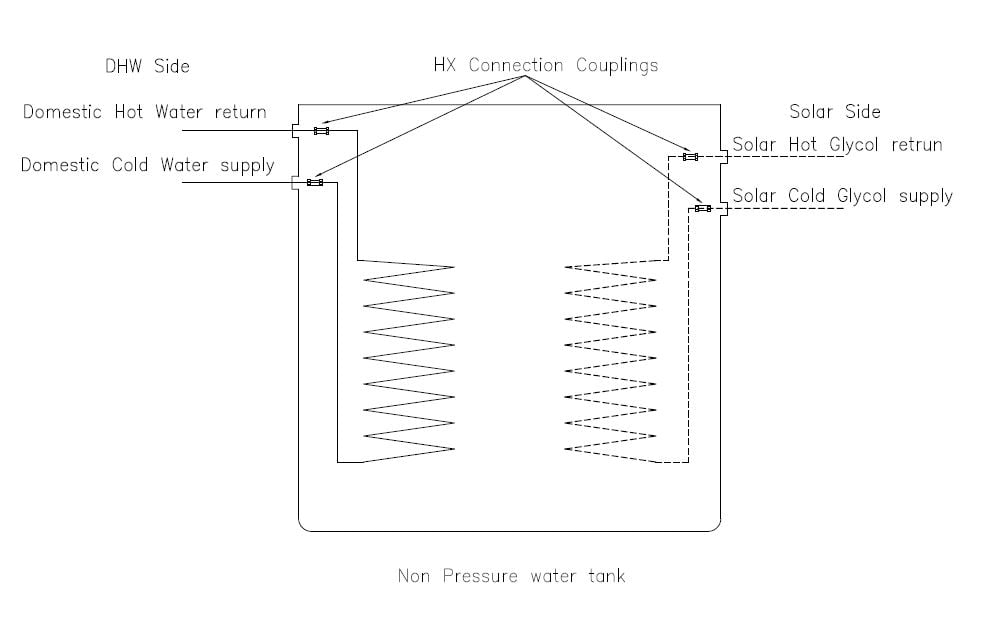

DHW&SolarSide Connection - HX

Connection used in single HX. Requires some additional elements like HX Connection Coupling. Applicable for connection HX on DHW side and Solar Side. One heat exchanger is connected to solar loop, there other is connected to DHW loop. There is a possibility to add more heat exchangers on both side. In this case you will need some extra elements like HX Connection Tees.

SolarSide Connection - HX

Connection used in single HX. Requires some additional elements like HX Connection Tees. The connection type uses only the Solar Side ports. There is no heat exchanger connected with DHW Side.

Why Sunmaxx Solar tanks have no electric back up elements?

Sunmaxx Solar tanks are typically used to pre-heat to an existing primary tank. This solutions has some advantages and its definitely more effective than installation the integrated heat source inside the solar tank. Pre-heating help to reduce the heat loses and price of electricity bills. The main factor of this solution is efficiency .Can I Connect Existing Installation To The New Tank?

Yes you can. But we are recommending to use dedicated parts to our installations. All products can be easily connected using the SunMaxx Solar products. Moreover they we designed to different type of connections. Changing the parts and system installation may led to some problems or improper way of working the system. If it is not enough for you , call us we will help you.- Steel (no.: 6837)

- Standard: DIN EN 10120

- Steel Quality: P245NB

- Internal Coating: double enameling (heated at 1580F) (vitrified steel)

Warranty

- 7 years limited on tank and coil heat exchanger

- 3 years limited on tank and coil heat exchanger in all commercial installations

Additional information

| Weight | 45 lbs |

|---|---|

| Dimensions | 45 × 60 in |