HelioMaxx™ 120G Glycol Solar Hot Water Evacuated Tube Collector Kit

$7,079.94

The HelioMaxx™ Prepackaged solar hot water kits provide an easy way to switch to solar and include all necessary components. The 120G glycol system is ideal for colder climates and can supply enough hot water for a household of 4-6 people.

- Description

Description

HelioMaxx™ 120G Glycol Solar Hot Water Evacuated Tube Collector Kit

Product Description

The HelioMaxx™ Prepackaged solar hot water kits make going solar easier then ever before! Our HelioMaxx™ residential kits have been designed by the SunMaxx engineering team to provide domestic hot water for your home using the best engineering practices available word-wide. All kits include the main system components including the solar storage tank, piping, controller, pump station, and glycol.

This 120G glycol system is ideal for colder, northern climates where freezing problems would damage or destroy other solar hot water systems and will provide enough hot water each day for a household of 3 to 6 people.

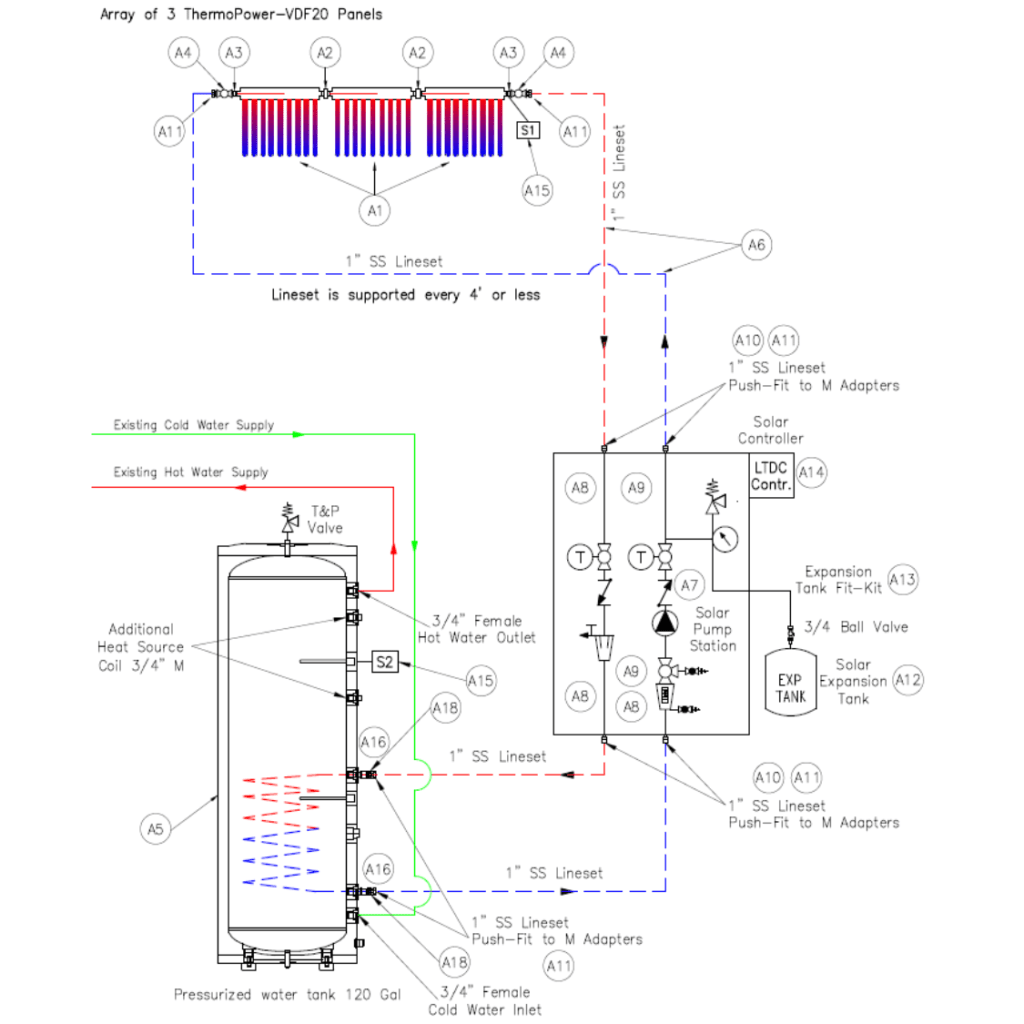

List of components

- 2x 1″x 1/2″ MIP x FIP Brass Bushing (Lead Free) (A3)

- 2x 1IN Ball Valve (Full Port Threaded) (A4)

- 4x 1′ Copper Pipe 1″ (A9)

- 4x 1″ Press to Female Adapter (A10)

- 8x 1IN Quick Connect fittings by SunMaxx™ (Male) (A11)

- 2x Bushing 3/4″ Male to 1″Female (A18)

Features & Benefits

- Over 50% subsidy

- StorMaxx Premium storage tank

- UniMaxx integrated pump station

- Patented innovative components

- Hassle-free installation

- Retrofits virtually any existing system

- 10 years performance warranty

- Comprehensive turn-key package

- SRCC & Solar Keymark Certified

- Manufacturer Direct Quality and Pricing

Technical Details

How to Size your Solar Hot Water System (DHW):

On average a homeowner uses approximately 20 gallons of hot water per day per person. Using this figure you can calculate which size prepackage system is suitable for your heating requirements.

If you are looking to utilize a solar hot water heating system for space heating needs please contact our solar hot water sales department so we may provide you with an accurate assessment of your heating requirements. Typically we are able to offset between 40-80% of your home heating needs with a payback period of less than 8 years.

Need Assistance?

If you have questions need help or simply feel uncomfortable placing your order online feel free to contact the product representative at 1-800-786-0329.

Specifications:

- Weight: 115 lbs (without crating)

- Dimensions: 79 in H x 70.2 in W

- Packaging: Ships via freight on a pallet or is available for local pickup (1 pallet is available for residential or commercial delivery )

- Assembly Time: A collector can be assembled in 1.5 hours

- Manufacturer: Silicon Solar Inc.

- Warranty: 3 Year limited (extended warranty available)

- Expected Lifetime: 25-30 Years

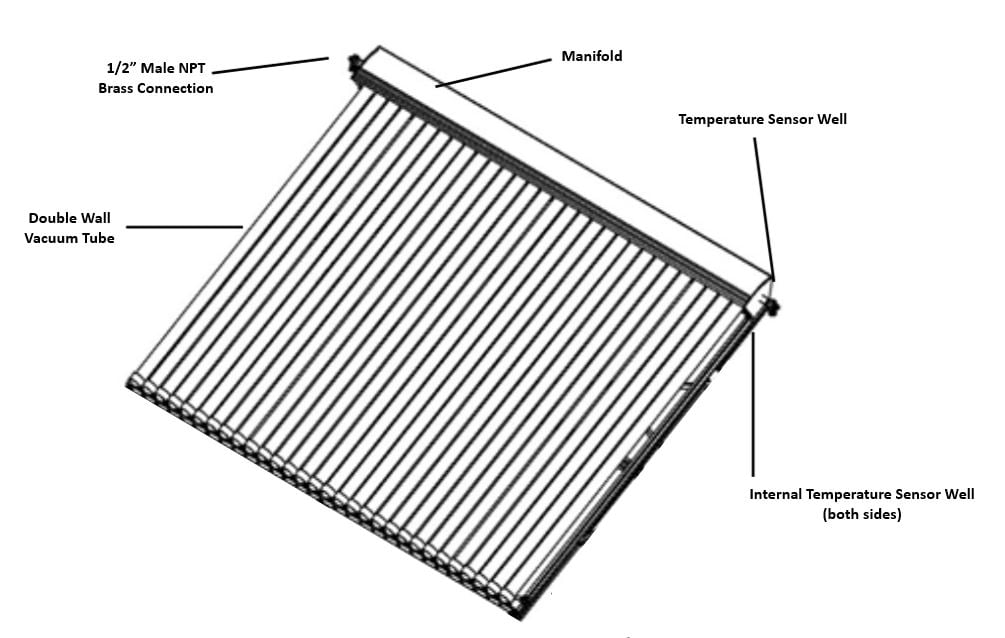

- Fitting: 1/2 NPT Male

Includes:

- Complete Flush and Tilt Mounting Face Frame

- Manifold (header)

- 20 Revolutionary SunMaxx Vacuum Direct Flow

- 20 Vacuum Direct Flow heat pipes

- Hardware for collector assembly

ThermoPower™ VDF Series Details:

- Tube Length (in)/(m) 59/1.5

- Outer Tube Diameter (in)/(mm) 1.46/37

- Inner Tube Diameter (in)/(mm) 1.36/34.5

- Tube Material Borosilicate Glass

- Tube Coating Al–N/Al.

- Thermal Expansion (in)/(mm) 3.3*10–6 / 84*10–6

- Coating Absorbance > 94%

- Coat Emissivity < 7%

- Vacuum (Pa) < 5×10–3

- Heat Loss (W/m2.oC) < 0.7

- Max. Pressure Thrust (MPa) 1.0

- Flow Rate per Tube (gpm/lpm) 0.02 / 0.08

- Tilt Angles (degrees) 0-90

- Orientation Portrait

- Max of Tubes in series 300

- Operating Pressure (psi)/(bar) 20–70/1.4–4.8

- Maximum Pressure (psi)/(bar) 150/10.3

- Stagnation Temperature (F/C) > 428/220

- Heat Transfer Fluid Water

- Heat Transfer Method Direct Flow Pipe

- Manifold Socket Soldered Dry Socket

- Glass to Metal Seal Type Hermetic

- Fittings 1/2” NPT

Model details:

- Dimensions (in)/(m) (WxH) 60.0 x 64.7/1.52 x 1.65

- Gross Area (ft2/m2) 26.95/2.50

- Net Aperture Area (ft2/m2) 19.26/1.79

- Absorber Area (ft2/m2) 11.41/1.060

- Weight (lbs/kg) 115 / 52.16

- Fluid Capacity (gal/L) 0.5/1.89

- Rated Flow Rate (gpm/lpm) 0.4/1.51

- Minimum Flow Rate (gpm/lpm) 0.2/0.76

- Maximum Flow Rate (gpm/lpm) 3/11.4

- Storage Tank Size (gal/L) 30–40/113.6–151.4

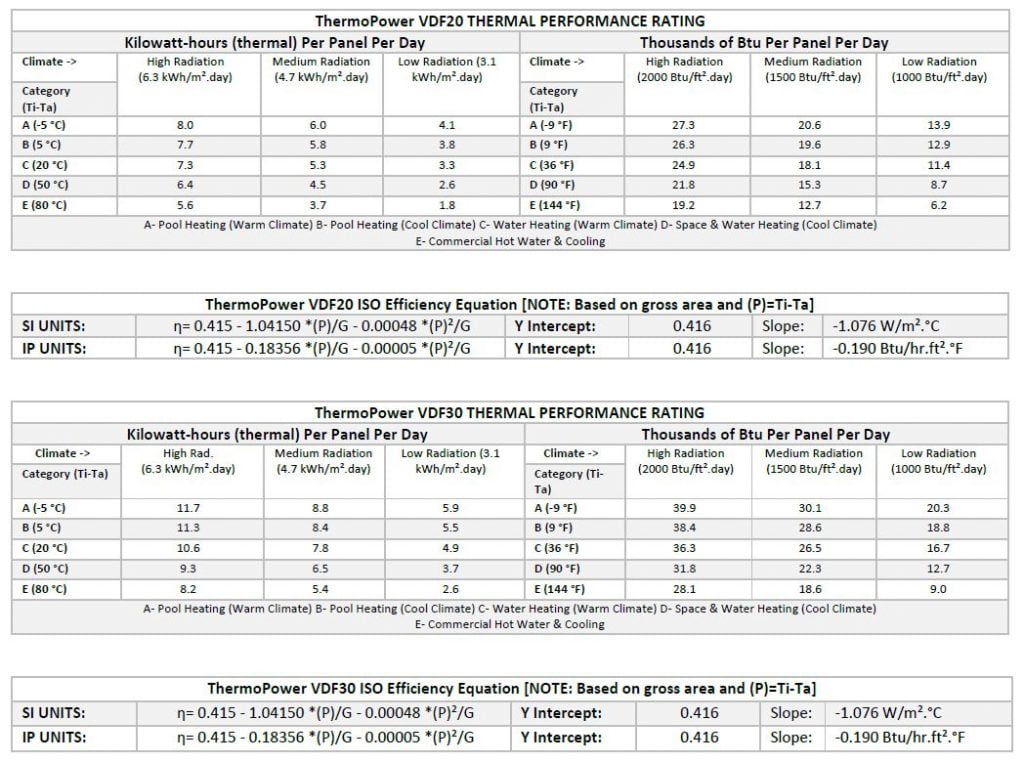

- SRCC Clear C Rating (kBTU/panel/day) 22.8

- SRCC CERTIFICATION # 201203H

Applications:

- Domestic hot water: Normal hot water for a house

- Radiant floor heating: Systems of any size

- Pool and spa heating: Large and small pools

- Residential hot water applications

- Commercial hot water applications

- Industrial hot water applications

- Municipal hot water applications

Glossary:

Tube Length: The length of the glass tube used in the solar thermal collector.

Outer Tube Diameter: The diameter of the outer glass tube of the solar thermal collector.

Inner Tube Diameter: The diameter of the inner glass tube of the solar thermal collector.

Tube Material: The type of glass used in the solar thermal collector.

Tube Coating: The coating material applied to the glass tube of the solar thermal collector.

Thermal Expansion: The change in length of the solar thermal collector due to temperature changes.

Coating Absorbance: The proportion of sunlight that is absorbed by the solar thermal collector coating.

Coating Emissivity: The proportion of absorbed sunlight that is radiated away as heat from the solar thermal collector coating.

Vacuum: The level of vacuum pressure maintained within the solar thermal collector.

Heat Loss: The amount of heat lost from the solar thermal collector per unit area due to conduction, convection, and radiation.

Max. Pressure Thrust: The maximum pressure that can be exerted on the solar thermal collector without damage.

Flow Rate per Tube: The rate of flow of heat transfer fluid through a single tube of the solar thermal collector.

Tilt Angles: The range of angles at which the solar thermal collector can be tilted for optimal performance.

Orientation: The preferred orientation of the solar thermal collector (either portrait or landscape).

Max of Tubes in series: The maximum number of glass tubes that can be connected in a single row.

Operating Pressure: The recommended range of pressures for the heat transfer fluid in the solar thermal collector.

Maximum Pressure: The highest allowable pressure for the heat transfer fluid in the solar thermal collector.

Stagnation Temperature: The maximum temperature that the solar thermal collector can reach when not actively transferring heat.

Heat Transfer Fluid: The type of fluid recommended for use in the solar thermal collector.

Heat Transfer Method: The method by which heat is transferred from the solar thermal collector to the heat transfer fluid.

Manifold Socket: The method used to connect the glass tubes to the collector manifold.

Glass to Metal Seal Type: The type of seal used between the glass tube and the metal collector manifold.

Fittings: The size of the fittings used to connect the solar thermal collector to the piping system.

The ability to convert solar energy into thermal energy is expressed by the optical efficiency of the system (ŋ0). The global solar radiation varies considerably from region to region. On a clear summer day approximately 850 W/m2 (270 Btu/ft2)can be expected, whereas clouds can reduce it to 400 Btu/ft2 (127 Btu/ft2)

Both Flat Plate and Vacuum Heat Pipe collectors are insulated to prevent heat loss, but due to extremely good insulation properties of the SunMaxx Vacuum heat pipe Solar Collectors, the “only” heat loss is via the SunMaxx Manifold with its small surface area and thick layer of high-quality polyurethane foam

insulation.

SunMaxx Evacuated Heat Pipe Solar Collectors can supply heat at temperatures significantly higher than those achieved by Flat Plate Collectors. This comparison is particularly relevant in cold, windy and cloudy climates. The following explanations are for installations of up to 90 tubes (4 Flat Plates).

While both types of collectors capture the suns energy and convert it to hot water each have there own advantages.

Evacuated Tube Collectors are best used in northern climates where freezing can occur and can be utilized in areas where temperatures drop down to -60°F. Evacuated Tubes are are extremely efficient by virtue of the Tubes themselves. Each Evacuated Tube is hermetically sealed meaning it is highly insulated due to the fact that it is a sealed atmosphere nearly impervious to outside temperatures. Evacuated tubes can also be replaced if damaged, simply by plugging it in, no need to replace the whole unit.

SunMaxx Flat Plate collectors use a highly efficient flat absorber material called Tinox which transfer heat to a series of copper tubes which circulate a 50% glycol/water mix. The collectors themselves are in essence a a sealed insulated box which captures the suns energy and transfers it via the Tinox, then through the pipes filled with glycol and into the storage tanks.

Yes you can. Collectors can be attached to our ballast system, which uses the weight of standard patio blocks to hold the collectors in place. Wind load calculations must be done by an engineer to conform to local building codes. With the proper weight attached, collectors will stay in place without putting any holes in the roof. This has been done with our evacuated tube collectors and our flat plates. Flat plates obviously have a much higher wind resistance, and therefore require greater weight to hold them in place. Our ballast system will work with photovoltaic panels as well.

There are no guarantees with rafters when it comes to distance apart or consistency. The easiest way to deal with this problem is using the ConnectMaxx rail system. Our roof mounts can be secured where the rafters are, and then our rails can be secured to the roof mounts. All of our collectors can then be secured anywhere along the rails using sliding blocks. When using SunMaxx rails, you can worry less about where the rafters are and more about where you want your collectors!

This answer depends on what you are trying to accomplish. For simple Domestic Hot Water systems you should try and position you collectors at the same angle as your latitude. For systems that are tied into the home heating system, as in a combisystem, you should position you collectors 15 degrees higher than your latitude. For summertime use only systems, as in a pool system, you should position your collectors at your latitude minus 15 degrees.

For systems that have a high solar fraction, i.e. 75% or greater, you should increase the angle of incline in order to decrease your summertime production slightly.

Do you want to make this system perform to its highest ability or should it look nice and fit the architecture of the house?

We have all seen those albatrosses on the roof that are cantilevered at a compound angle to get a few extra BTU’s at the cost of aesthetic appeal. Here are some guidelines to consider when deciding what is most important in determining collector orientation and inclination.

For most collectors, tubes or flat plates, the angle of inclination has a 30 degree window of variation and the performance will still be within 95% of the expected maximum. That is, if your collectors should be mounted at 55 deg then you can mount them between 40-70 while losing only a small fraction of energy gain.

As for the collector orientation, that window is 60 degrees for Evacuated tubes and 30 degrees for flat plates. These considerations allow you to fit the collector to most homes’ pitch and orientation without losing too much energy gain.

Obviously you want your client to get the most out of it, but you are more likely to get additional jobs if the collectors are mounted in a way that takes into account the aesthetic appeal. Ask your Sunmaxx Representative for a copy of the Inclination and Orientation performance Chart so you can make informed decisions.

Yes it is. Depending on your type of collector, you can program your controller to manually activate the circulator which will bring heat from your storage vessel and into the collectors, which will radiate that heat back out thus melting the snow. This method only works for FLAT PLATES however and will usually take as much energy as it makes. When the sun is out in full force, the rays passing through thge snow are typically enough to create substantial heat that in turn, melts the snow on flat plates.

For Evacuated tubes however, there is very little you can do to melt the snow. If your collectors are sitting at a tilt off from the roof pitch, you should be okay because the snow will pass between the tubes onto the roof. But for flush mount EVT systems, snow can and will build up. However, in my experience, this will only affect the output for a day or two. Becuase if the sun is out enough to make any amount of BTU”S then there will be enough heat wasted at the roof/collector interface that begins to melt the snow alowing it to slide down from the top of the tubes. With only minimal exposure to the direct sunlight, the small amount of exposed tube will begin to yield significant amount of BTU’s, even though they are mostly covered. So for tubes, dont sweat it, you are not going to lose much unless of course they get covered by a couple feet or so then perhaps you’ll want to sweep them off if you can.

This will be a debate well in to the future. For an more in-depth review please watch this Click here to watch this 1/2 hour webinar. Your decision should be based primarily on the following considerations:

- Temperature demand– What is you existing application? EVT’s will outperform FP’s at higher temp load.

- Climate location- In a general sense, flat plates have more value than evacuated tubes in warmer climates and EVT’s will do better in cold, cloudy climates.

- Aesthetics appeal– This is where there is no “right” answer. Instead, each person has their own personal view. We recommend that you go with it. If they prefer flat plates for that reason then you install flat plates and if they prefer evacuated tubes for their aesthetic appeal, then by all means, you should install Evacuated tubes.

The point is, you really CANT GO WRONG. Each type will yield significant value and in the end, the differences will be negligible.

Fortunately, solar thermal collectors are not nearly as sensitive to light conditions as PV collectors. As for performance, you have roughly a 60 degree window of opportunity to mount the collectors toward south before you begin losing a small bit of total production. In other words, your house can be situated 30 to the east of true south or 30 degrees to the west of true south and your performance will still be at or above 95%.

As far as tilt angle goes, this window opportunity is slightly smaller but still you can have a roof pitched about 20 degrees plus or minus of your particular latitude angle and you will still see results at or above 95% of expected.

Ask a SunMaxx rep to run a Polysun report for your particular conditions to be sure, you will be happy you did and pleasantly surprised.

Replacement Evacuated Solar Tubes

We recommend the below accessories.

Replacement Evacuated Solar Collector Parts

We recommend the below accessories.

Collector Connection Accessories

We recommend the below accessories.

Evacuated Tube Collector Accessories

We recommend the below accessories.

Evacuated Tube Collector Accessories

How to Order:

If you are confident with your solar hot water heating requirements you can place your order online by clicking on the add to cart button which is located above. All orders are reviewed by our solar hot water heating department and the customers are contacted in order to ensure that you have ordered the correct merchandise for your application. In the event you have any questions our sales staff are available from 8:30AM to 5:30PM EST.

Silicon Solar Inc ships products internationally please ask your sales representative for a shipping rate to your destination.

Need Assistance?

If you have questions need help or simply feel uncomfortable placing your order online feel free to contact the product representative at 1-800-786-0329.